Writer: admin Time:2024-01-17 14:42 Browse:℃

What's the Advantage of 5 axis cnc router

5-axis machining offers three linear axes and two rotational axes that work simultaneously to achieve complex surface machining. The 3+2-axis machining offers a 3-axis milling process, with two additional axes to rotate the hold tool in a fixed position as opposed to manipulating it repetitively during the machining process.

A 5-axis machine helps you work on tighter tolerances to achieve complex geometries while a 3+2 system allows you to hold your less complex parts in positions that allow better access to the features.

Beyond the three linear axes, 5-axis CNC machines add two axes, typically called the A-axis and B-axis. These two additional axes enable 5-axis machines to tilt and rotate the cutting equipment or parts to produce more sophisticated geometries than 3-axis machines.

These make 5-axis machines the secret to producing highly precise components without seams or signs of welding. 5-axis machining capabilities have transformed manufacturing industries, such as Automotive ,healthycare aerospace , agriculture 3d carving .etc

Aerospace – this industry requires a very precise machine, as the shapes are very intricate and unique.

Medical – 5-axis CNC machining can help manufacturers of medical equipment in the production of devices, implants, as well as other pieces of equipment that need to be made with extra precision in order to meet healthcare standards which tend to be rigorous (rightfully so).

Military – another industry that uses 5-axis CNC machining to produce the needed parts. Some of the possible applications include submarine parts, high-performance engine parts, turbine and compressor blades, smart weapons, sensors, stealth applications, as well as, in some cases, nuclear weaponry.

Energy equipment – producing parts for energy equipment often requires using materials that are hard to work with. With 5-axis CNC machining, you can make the whole process easier and more efficient.

Material :

5 axis cnc application

plastics by vacuum forming

Aeroplane new energy parts making

carbon material

Foam mold

composite material mold making milling trimming

Transfer of molds from MDF to fiberglass

The mold from MDF

thermoplastics

Glass and carbon fiber reinforced duroplastics

Molded parts made of GMT and SMC

Molded parts made of foam, leather and a carrier part using the sandwich technique

wood paneling

plywood moldings

Honeycomb lightweight materials

blow molded parts

Model construction foams in tool and model construction

Increased Flexibility:

The additional two axes allow for more complex and intricate cuts and shapes to be achieved. This is particularly useful for industries such as aerospace, automotive, and medical, where intricate and complex parts are common.

Minimized Setup

A 5-axis machine allows you to work on every surface, apart from the clamping area and the bottom. When working on contoured parts or parts that require machining on several faces, you need several setups of the 3-axis machine to achieve the complex geometry through manual rotating; 5-axis technology completes the job in a single setup, reducing the number of setups and helping you save time.

Higher Precision and Accuracy

5-axis CNC machines operate with greater precision to deliver accurately machined and smoother parts that would be too complex for machining on traditional 3-axis CNC equipment.suntec 5 axis cnc routerin order to make sure high precision from welding adope 12mm thickness 300*500mm square tube then enforced steel inside also used worldfamous parts such as italy Demas 5 AXIS HEAD l TYPE OR U type , italy hitec spindle japan aboslutely driver and motor TPA osai or syntec controller to make sure high precision . Suntec 5 axis working table cast iron table one table from 5-20t according your working material to decide which also can make sure high precision . suntec 5 axis cnc router all finished used Reinshaw laser Articulated arm polyworks leica laser all test his precision to make sure all within 0.1mm then delivery below is used polyworks double laser to test suntec 5 axis cnc router precision . two laser all past .

Higher speed

5-axis machining enables the involvement of shorter cutting tools considering that the head can be dropped and cutter oriented to the surface. You can get higher cutting speed and tool vibration as well as you can expect the best results.

Shorter Cutting Tools

5-axis machining enables you to use shorter cutting tools because you can lower the head and orient the cutter appropriately. This helps achieve higher cutting speeds without putting too much pressure on the cutter. Shorter cutting tools also reduce the vibration of the tool, which may cause cavities and cores. Since 5-axis machines have less vibration, you’ll see a better surface finish.

Cost savings can make a big difference right away and in the long run. While 5-axis CNC machines may have a higher upfront cost than 3-axis or 4-axis machines, they can help to reduce costs in the long run by improving part quality, reducing scrap rates, and increasing productivity.

Improved Surface Finish

The ability to tilt and rotate the cutting tool in multiple directions allows for better access to the workpiece, resulting in improved surface finish and overall part quality.

Above all ,5 axis cnc router have many advantages , according your working size and material to choose best one . you can just tell us

what your working size ? length width heihgt

what material you deal ? styrfoam wood foam EVA PP Aluminum carbon material fiberglass or other material we will make best suggestions plan for you .

SUNTEC 5 AXIS CNC Working CASE

SUNTEC 5 AXIS CNC Router 3*12m (118*472inch ) z axis 2000mm (78inch) in Thailand customer workshop for boats making . normal this size need large size such as 3000*5000mm(118*196inch) 5000*8000mm(196*314inch ) 3000*6000mm(118*236inch ) 5000*12000mm(196*472inch ) size to make boats some customers make yacht some make big one need parts by parts to make , z axis some need high 2000mm 3000mm etc

SUNTEC 5 AXIS CNC ROUTER IN KOKLER BATHROOM PARTS MAKING WHICH USED ST-2030 (2000*3000*1000mm )5 AXIS CNC ROUTER CAST IRON TABLE

Suntec 5 axis cnc router ST-1530 for composit material small boats in USA

SUNTEC ST-2030 5 axis cnc router for plane parts making

Heavy suntec 5 axis cnc router ST-2050 for aluminum parts making with water cooling spindle with water device table with water-proof device

and water tank

SUNTEC ST-2025 5 axis cnc router for marble cutting in Peru

suntec ST-1218 two table for new energy car battary making

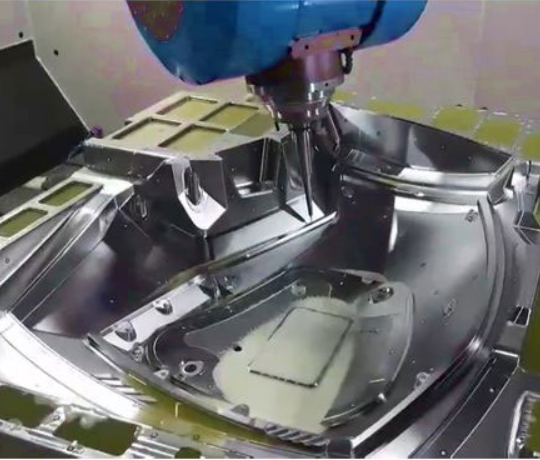

suntec ST-2030 5 axis cnc router for car parts mold making

suntec Economy one ST-1325 for fiberglass making and carbon material mold car making

ST-2030 5 axis cnc router for hard wood mold making

Other suntec 5 axis cnc router

Ancient house making in Thailand

ST-1525 for small piece wood furniture making for USA

PTP 5 axis cnc router for hard wood furniture

Phone: +86 15910100309

Tel: +86 15966606596

Email: info@sunteccnc.com

Add: 13908 Factory licheng district jinan city