SUNTEC 7 Axis Robot Arm Cnc 3D Sculpture7-axis robot with linaer units

KUKA 210 Details

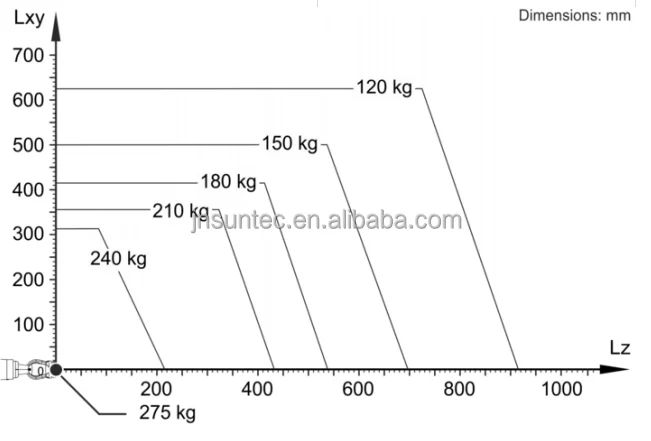

Load (refers to the load of point at the foremost end of the 6th axis) | 210kgs-3100 | |

Additional load on the arm | 50kgs | |

Rated payload | 260kgs | |

Maximum payload

| 275kgs | |

Weight | 1077kgs | |

Motion axis | 6 | |

Pose repeatability (ISO 9283)

| ± 0.05 mm

| |

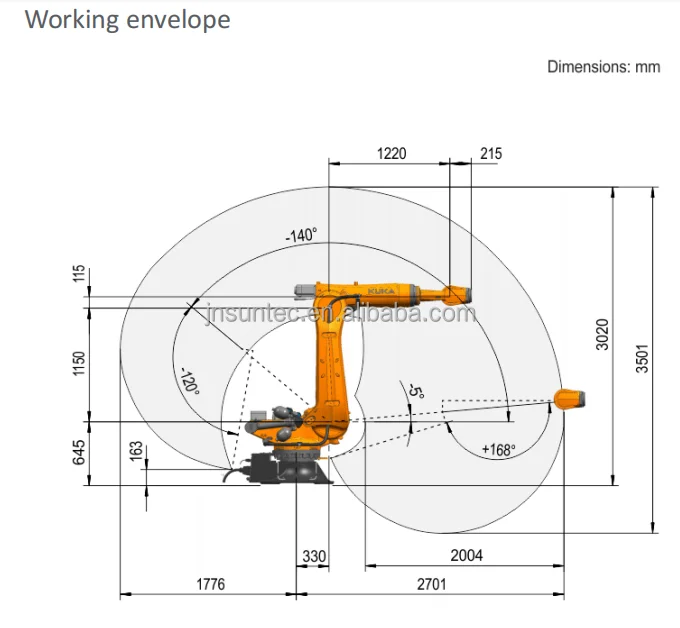

Maximum reach

| 2700mm/3100 | |

Protecton ratng (IEC 60529)

| IP65

| |

Protection ratng, in-line wrist (IEC 60529)

| IP65 / IP67

| |

Sound level

| < 75 dB (A)

| |

Mountng positon

| Floor | |

Footprint

| 754 mm x 754 mm

| |

Hole patern: mountng surface for kinematc system

| S780

| |

Permissible angle of inclinaton

| ≤ 5 °

| |

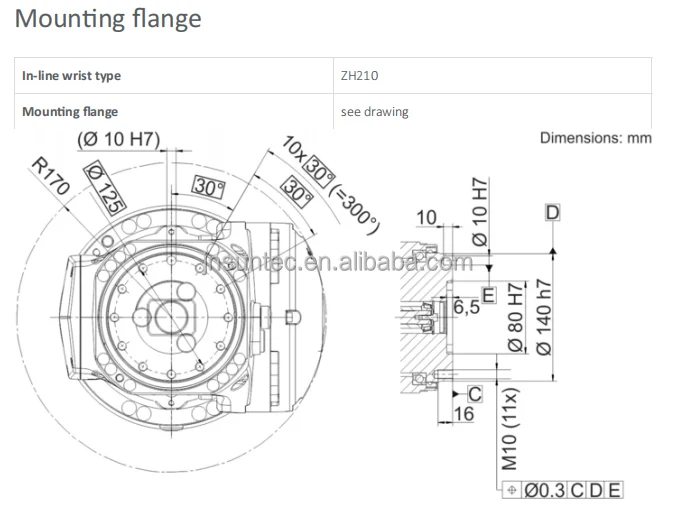

Flange (on the 6th axis) | DIN ISO 9409-1-A50 | |

Controller | KRC4 | |

Transformaton name

| KR C4: KR210R2700_2 C4 FLR

| |

During operaton

| 0 °C to 55 °C (273 K to 328 K)

| |

During storage/transportaton

| -40 °C to 60 °C (233 K to 333 K)

| |

Installation position | On the ground | |

CPU and main board | KUKA | |

Rotart table | 1500kgs china made | |

Spindle with water cooling systerm | 18kw Italy spindle | |

Software | Sprutcam

| |

DeviceNet

| OMRON | |

RAILS | 5M/6M/7M/12M/25M | |

Motion parameters of each axis | Range of motion | Speed |

Axis 1 | +/-185° | 120°/s |

Axis 2 | -5°/-140° | 115°/s |

Axis 3 | -120 ° / 168 °

| 112°/s |

Axis 4 | +/-350° | 179°/s |

Axis 5 | +/-125° | 172°/s |

Axis 6 | +/-350° | 220/°/s |

Main parts

KUKA SMART PAD

All KUKA robots running on KSS and Sunrise.OS can be operated in the desired language using the KUKA smartPAD. The KUKA smartPAD is hot-pluggable and can thus be connected and disconnected at any time.Efficient operationInputs are made quickly and easily via a brilliant, capacitive touch display with an 8.4" screen and high luminosity.Comfortable handling .

Two easily accessible USB ports enable direct saving and loading of application programs and connection of other supported USB devices

The KR C4 concept is revolutionary. For the first time, Robot and Motion Control are seamlessly and interactively integrated with control processes for PLC, CNC and Safety. With simple and flexible robot programming via inline forms and new Spline motion programming, KR C4-based automation solutions are superior in every way. Furthermore, the KR C4 features intelligent, flexible and scalable application potential.

The controller works reliably with different mains voltages and types, even in extreme cold, heat or humidity. It speaks 25 languages – including the major Asian ones – and meets all globally relevant ISO and US standards.

Kuka is 6 axis itself if you do carving milling routing within250mm diameter material such as wood foam stone fiberglass or other composite material . can add one spindle

is enough , normal we use italy hitec spindle 12-18kw according your material thickness .

italy hitec spindle 12kw watercooling 24000rpm hsk-f63 tool holders. high precision

low noise IP55 degree protection 380v .

if your material large than 250mm need squar rails to support , square rails length according your material diameter to choose now hot sales 5m 6m 7m 10m 25m etc .

according your material to choose right robot type . then according robot type to choose rails foundation . all our foundation used high rigidity steel welded to make sure robot move smoothly .

suntec will give you install solutions and drawing before you buy

Others robot install ways according your working material size to choose

working sample

Kuka robot for Yogi wood carving

KUKA robot in France customer workshop for windpower making hole

kuka ROBOT IN Indonesia workshop for Art carving engraving and 3d Status

kuka robot for sanding transformer with camera

kuka 7axis robot in USA customer workshop for hardfoam making for bathroom parts making two robot working together saving labor cost

Kuka robot in Thailand workshop

Kuka robot in Russia customer workshop for wood car mold making

KUKA robot in Saudarab for marble carving

7 AXIS ROBOT WITH LINEAR UNITS FOR INSTALLING

7 AXIS ROBOT WITH RAIL WAYS LINEAR UNITS FOR WELDING

packing details

Phone: +86 15910100309

Tel: +86 15966606596

Email: info@sunteccnc.com

Add: 13908 Factory licheng district jinan city